|

| 1 |

|

| 2 |

|

| 3 |

In the current economic climate it is more important than ever for businesses to reduce their overheads. Saving energy is a good place to start.

Here are five simple tips to help you cut carbon, consumption and costs.

1. Switch off at nights and weekends

It might sound obvious, but companies still waste thousands of pounds by leaving equipment switched on overnight.

The Carbon Trust has reported that office equipment is the fastest growing area of business energy consumption – it accounts for around 20% of total energy use.

Computers and their monitors are some of the worst offenders. Turning off your company's PCs at evenings and weekends could cut your running costs by more than two thirds.

Switching off vending machines, printers and water coolers during these times can also reduce their energy use by as much as 70%.

Endeavour to switch off all equipment at night and turn off any machines without on/off switches at the plug.

2. Don't leave equipment idling

You can make even more savings during the day by making sure equipment is not left running for nothing.

An idling hosepipe, for example, can waste up to 18 litres of water every minute. If it isn't in use, the tap should be turned off.

A computer screen can use as much energy when displaying a screensaver as it does during normal use. If you switch it to sleep mode instead, you could cut its energy consumption by up to 70%.

Chargers and adaptors should be turned off unplugged as soon as equipment has charged and whenever they are not in use.

3. Report defective equipment

Equipment and vehicles can waste both energy and resources if it not running properly or efficiently. A faulty piece of equipment may also present a risk to safety.

Defects may worsen during prolonged use and this may make the equipment more difficult and costly to repair.

Employees should be alert for any strange noises, changes in handling or process problems.

First-use checks should be carried out before using any vehicle or piece of equipment and any problems tshould be reported.

If a fault develops during operation, it should be reported immediately and further use should be suspended until the problem is addressed by a qualified service person.

Any defective equipment should stay out of service until the problem is rectified or until it is authorised for use.

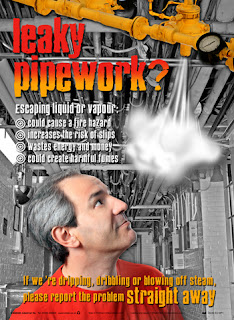

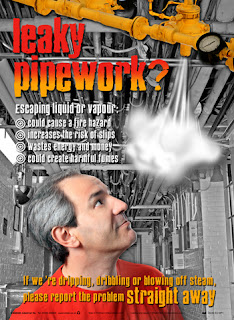

4. Report leaks

Most leaks are a sign of energy wastage. They may come from a range of sources including dripping taps, perished hoses, cracked tanks, broken pipes and defective machinery.

Leaks may include steam/vapours, oil, fuel or water. Extra care should be taken if any leaked material also poses a fire hazard or slip risk.

Employees should be alert for visible steam, dripping liquids, puddles on the ground, sounds of air or liquid escaping and any drop in pressure from equipment they are using. Again, the advice is to report the problem as soon as possible.

5. Ask for suggestions

Employees working directly with your equipment, vehicles and machinery are generally more aware of the waste that is being created and often have clever suggestions that could help reduce it.

Asking your employees for help and ideas is proven to make them feel more valued and can improve their performance at work, so it could be a win-win situation.

If you would like to find out more about how our posters can help your company save energy, please

contact us.

For daily tips on dealing with common workplace issues, why not follow us on Twitter.

If you would like to find out how Kodiak posters

can help your business work smoother, smarter

and safer, please call us on: 01530 456 000

or email us.